Tapping into the Strength and Flexibility of 300 x 63mm LVL Beams

In the context of contemporary construction, the utilization of 300 x 63mm LVL beams (Laminated Veneer Lumber) showcases a fusion of strength, adaptability, and ecological soundness. Comprising layers of bonded thin wood veneers, these beams offer a unique blend of robust load-bearing capacity and consistent dimensions. This introduction explores the diverse potential of these beams, accentuating their effectiveness in various structural applications, economical aspects, and environmentally conscious features. From housing ventures to commercial undertakings, grasping the inherent capabilities and versatility of LVL beams unravels fresh possibilities in architectural design and construction, ushering in a novel era of innovation.

Refer to the Specifications below for specifications on the major types of LVL formwork supplied by ROCPLEX or contact us to discuss further your needs.

Refer to the Specifications below for specifications on the major types of LVL formwork supplied by ROCPLEX or contact us to discuss further your needs.

Please contact our sales team for more detailed information regarding ROCPLEX – SENSO Structural LVL.

LVL Beams 300 x 63mm FAQ

Q: What is an LVL beam?

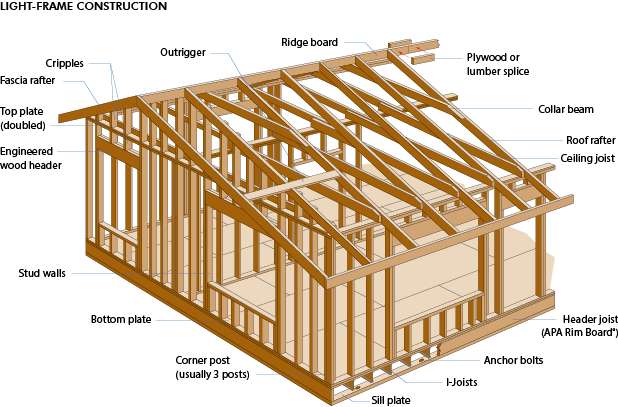

A: LVL beam is a type of engineered wood product made by laminating thin layers of wood veneers together to create a strong and durable beam. LVL beams are commonly used in construction as a structural support members for roofs, floors, and walls.

Q: What are the dimensions of a 300 x 63mm LVL beam?

A: The dimensions of a 300 x 63mm LVL beam are 300mm wide (from face to face) and 63mm thick (from top to bottom).

Q: What is the maximum span for a 300 x 63mm LVL beam?

A: The maximum span for a 300 x 63mm LVL beam will depend on a variety of factors, such as the load that the beam will be supporting, the type of wood species used in the beam, and the spacing between the supports. It is recommended that a structural engineer be consulted to determine the appropriate span for a given application.

Q: What are the advantages of using LVL beams over traditional solid wood beams?

A: LVL beams have several advantages over traditional solid wood beams, including greater strength and stiffness, dimensional stability, and resistance to warping, twisting, and splitting. Additionally, LVL beams are less prone to shrinkage and swelling than solid wood beams, which can reduce the risk of structural damage over time.

Q: Can LVL beams be cut to size on-site?

A: Yes, LVL beams can be cut to size on-site using standard woodworking tools, such as circular saws and handsaws. However, it is important to follow the manufacturer’s instructions and recommendations for cutting and handling LVL beams to ensure their structural integrity is maintained.