SENSO LVL E13 Beams: 300 x 63mm H2S Treated

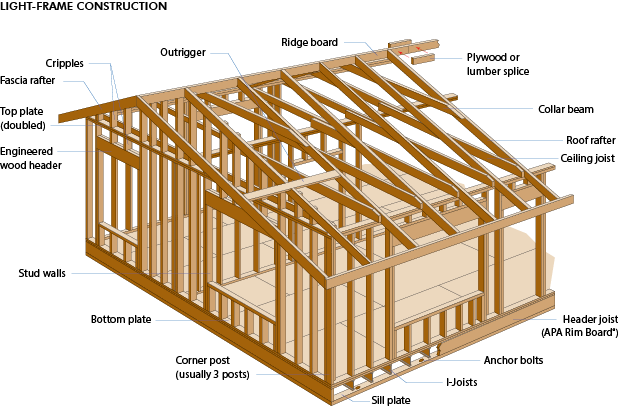

LVL Beams 300 x 63mm Laminated veneer timber, LVL E13, a type of ‘engineered wood product’ created in the 1960s, is made by adhering layers of wood veneers with the grain running parallel to one another. Beams made of laminated veneer timber can be constructed using several beams to increase strength and capacity

|

Container Type |

Pallets |

Volume |

Gross Weight |

Net Weight |

|

20 GP |

6 pallets |

20 CBM |

20000KGS |

19500KGS |

|

40 HQ |

12pallets |

40 CBM |

25000KGS |

24500KGS |

Meanwhile, we also can supply you the formwork system accessories, commercial plywood, film-faced plywood, etc.

We are specially professional in supplying LVL and plywood board.

Please contact our sales team for more detailed information regarding ROCPLEX – SENSO Structural LVL.

LVL Beams 300 x 63mm FAQ

Q: What are LVL beams used for?

A: LVL beams are used for structural support in a variety of construction projects, including residential homes, smaller commercial buildings, and other mid-range span applications.

Q: How strong are LVL beams?

A: LVL beams are very strong and can support moderate to heavy loads. The strength of an LVL beam depends on its size and the number of veneers used to create it.

Q: Can LVL beams be used for outdoor applications?

A: Yes, LVL beams can be used for outdoor applications, but they should be treated with a weather-resistant coating to protect them from moisture and other environmental factors.

Q: Are LVL beams more expensive than solid wood beams?

A: LVL beams can be more expensive than solid wood beams, but they offer several advantages, including greater strength and dimensional stability, which can make them a cost-effective choice in the long run.

Q: How are LVL beams installed?

A: LVL beams are installed using traditional framing methods, such as bolting, nailing, or screwing them to other structural members. It is important to follow the manufacturer’s installation instructions to ensure the proper installation of LVL beams.