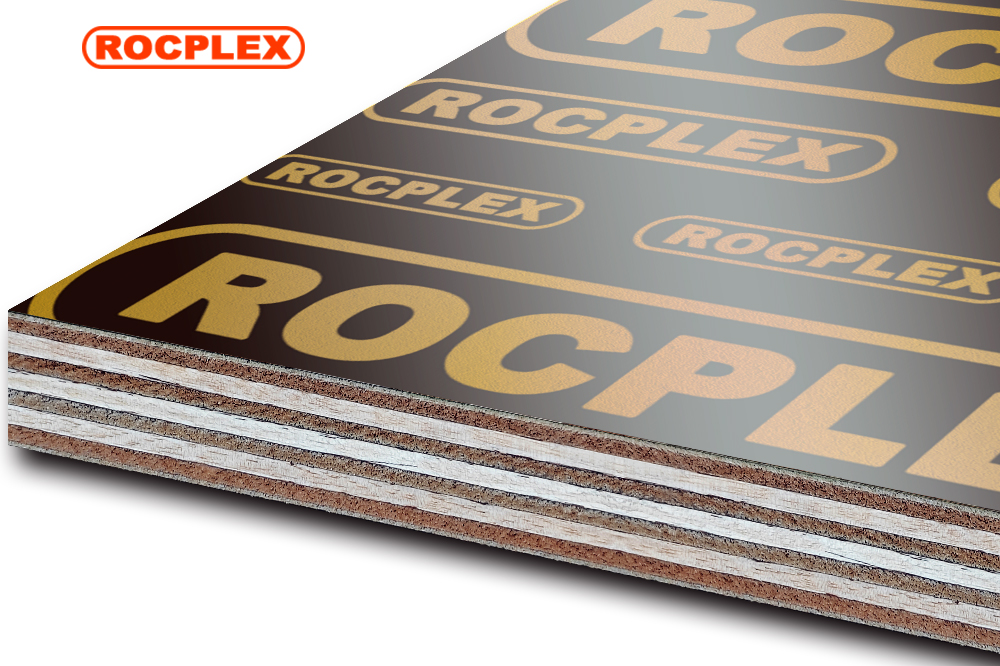

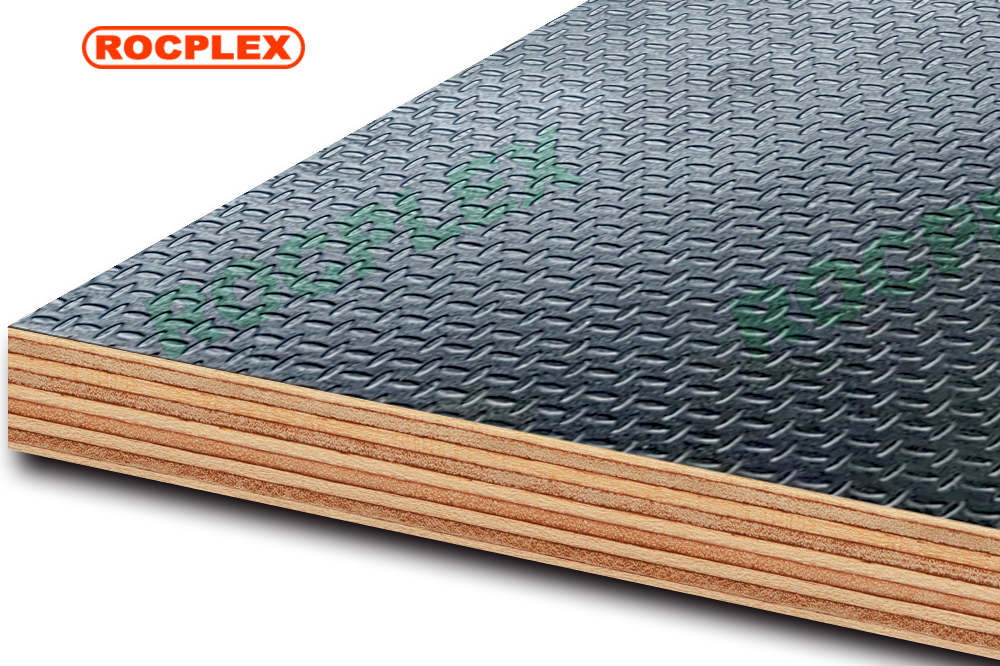

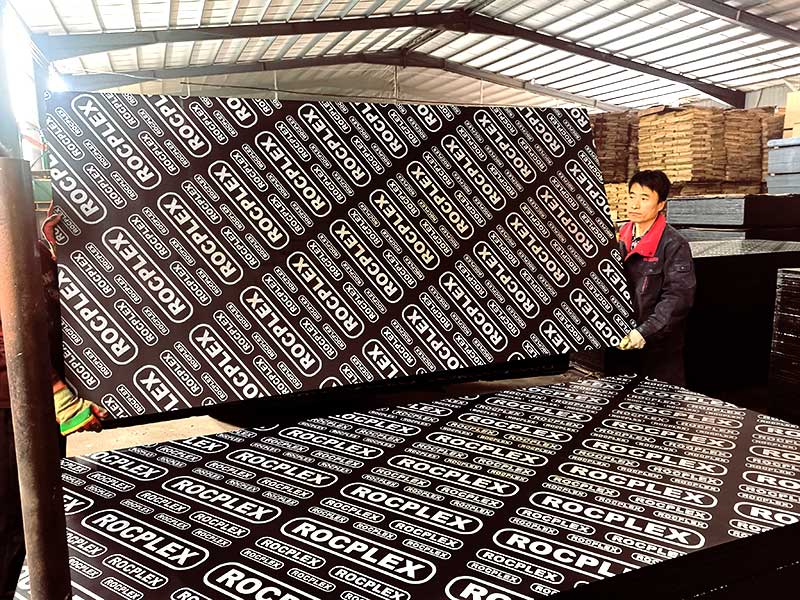

Robust Shuttering Plywood for Construction

Shuttering is a temporary mold or structure used to keep freshly poured concrete in place until it dries and has enough strength to sustain itself. This procedure is critical for achieving the required shape, design, and structural integrity of different concrete structures, such as buildings and bridges, as well as dams and tunnels.

ROCPLEX 15mm Film Faced Shuttering Plywood Technical characteristics

| Sr No. | Property | Unit | Test Method | Value Of Test | Result | |

| 1 | Moisture Content | % | EN 322 | 7.5 | Check out | |

| 2 | Density | kg/m3 | EN 323 | 690 | Check out | |

| 3 | Bonding Qality | Bonding Qality | Mpa | EN 314 | 1.68-0.81 | Check out |

| 4 | Bonding Qality | Damage Rate | % | EN 314 | 85% | Check out |

| 5 | Bending Moudulus of Elasticity | Longitudinal | Mpa | EN 310 | 6997 | Check out |

| 6 | Bending Moudulus of Elasticity | Lateral | Mpa | EN 310 | 6090 | Check out |

| 7 | Longitudinal | Mpa | EN 310 | 59 | Check out | |

| 8 | Lateral | Mpa | EN 310 | 43.77 | Check out | |

| 9 | Cycle Life | About 15-25 Repeated Using Times Acoording To Projects By Formwork Application | ||||

Uses of Shuttering in Construction

Forming concrete: The fundamental function of shuttering is to form and shape concrete using form plywood while it cures. It enables builders to generate elaborate shapes and accurate forms that are essential to architectural and structural needs. shuttering boards allows you to see the clean lines of a modern structure or the curves of an artistic sculpture.

Structural Strength: Shuttering not only imparts the appropriate looks but also assures the end product’s structural integrity and strength. By keeping the concrete in place during the first curing process, it eliminates distortions and ensures the concrete achieves its desired load-bearing capability.

Customization: Shuttering allows for building flexibility by allowing for customisationusing concrete forming wood. Contractors may bring the architect’s concept to reality by creating molds of various forms and sizes, resulting in distinctive constructions that stand out.

Speed and Efficiency: Using shuttering expedites construction processes. Pre-fabricated forms can be quickly assembled, saving time on site. This efficiency is especially beneficial for projects with tight timelines.

Safety: The use of shuttering speeds up building operations. Pre-fabricated shapes may be swiftly constructed on-site, saving time. This efficiency is especially advantageous for tasks with short deadlines.

Finally, shuttering is a necessary method in modern building. It adds to the strength, beauty, efficiency, and safety of building projects in addition to just storing wet concrete. Shuttering, with its capacity to accommodate a broad range of forms and constructions, is a monument to the inventive methods that continue to influence the built environment.

ROCPLEX Brown Film Faced Plywood Save Time, Labor and Cost

|

ROCPLEX Film faced plywood Save cost |

||

|

Be special for phenolic glue and film |

The smooth plywood film faced plywood can be disassembled and used repeatedly for both faces,saving 25% of the cost. |

|

|

Optimization for the special grade of core |

||

|

Be special for adhesive |

||

|

ROCPLEX Film faced ply wood Shorten duration |

||

|

Excellent effect of demoulding |

Shorten 30% of the duration. |

|

|

Avoid the reconstruction of the wall |

||

|

Be easy to incise and blend |

||

|

ROCPLEX Film faced ply wood the high quality of casting |

||

|

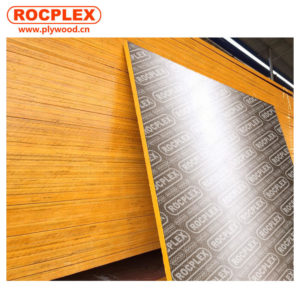

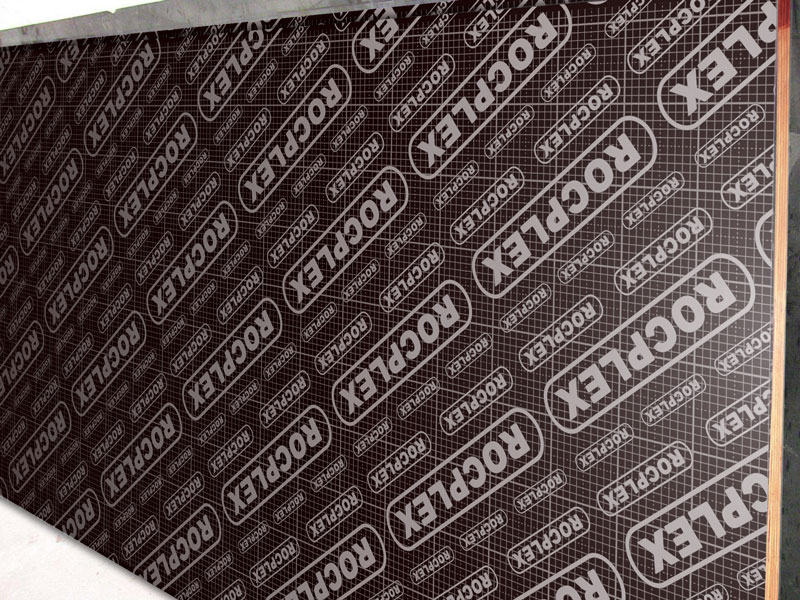

The flat and smooth faces |

The faces are flat and smooth, avoiding bleeding out remains of bubbles and concrete. |

|

|

The structure of waterproof and breathability |

||

|

The edges are polished carefully |

||

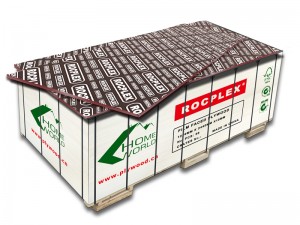

ROCPLEX 15mm Film Faced Shuttering Plywood Packing and Loading

|

Container Type |

Pallets |

Volume |

Gross Weight |

Net Weight |

|

20 GP |

8 pallets |

22 CBM |

13000KGS |

12500KGS |

|

40 HQ |

18 pallets |

53 CBM |

27500KGS |

28000KGS |

Meanwhile we also can supply you the concrete forming wood, commercial plywood, three quarter plywood and etc.

We specially professional in supplying form plywood shuttering boards .

Please contact our sales team for more detailed information regarding shuttering boards.

best plywood for subfloor

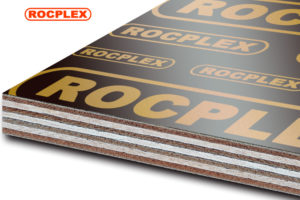

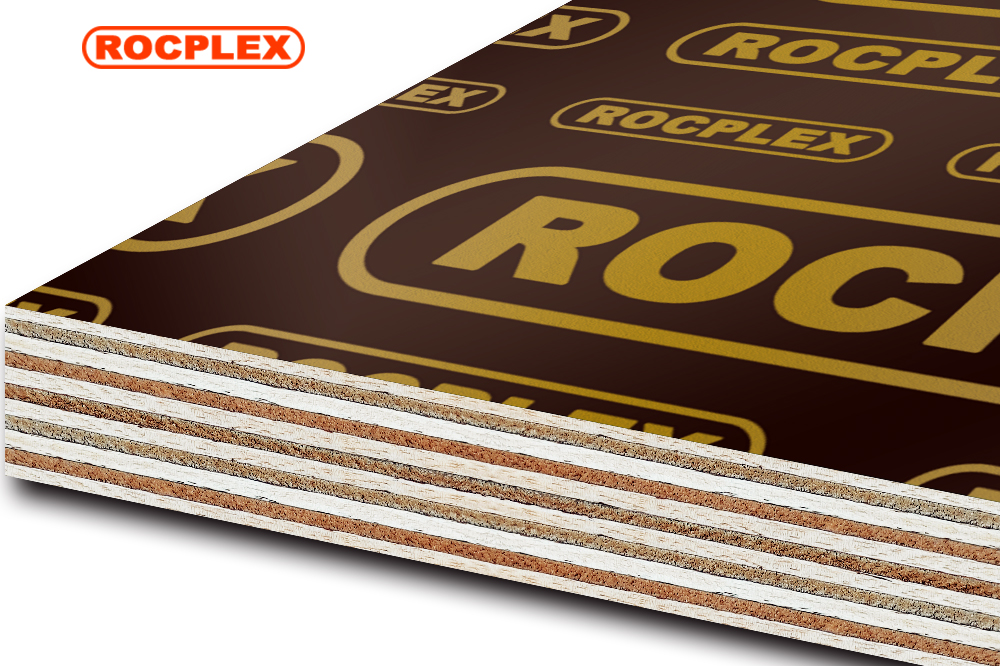

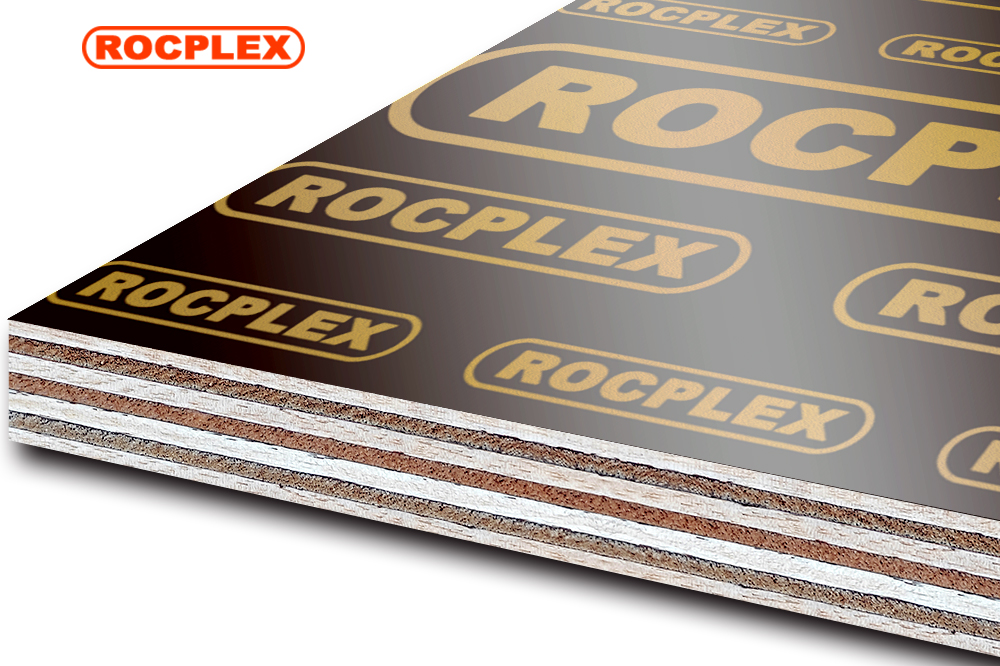

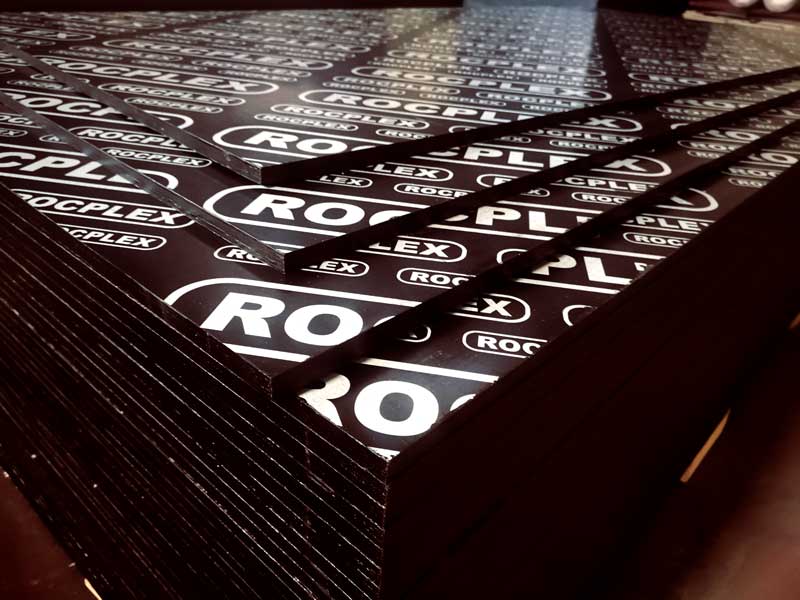

ROCPLEX Brown Film Faced Plywood

The film faced plywood is specifically designed for shuttering applications, making it easy to create smooth and even concrete surfaces. It prevents the leakage of cement slurry, resulting in high-quality finishes and reducing the need for additional surface treatment.

Brown Film Faced Plywood 15mm FAQ

Q: What is Brown Film-Faced Plywood?

A: Brown Film Faced Plywood is a type of plywood that has a brown film overlay on both sides, which provides a smooth and durable surface. This type of plywood is commonly used in construction and building projects, such as in formwork, roofing, and flooring.

Q: What are the dimensions of Brown Film Faced Plywood 15mm?

A: Brown Film Faced Plywood 15mm typically comes in standard sizes of 1220mm x 2440mm (4′ x 8′).

Q: What is the thickness tolerance of Brown Film Faced Plywood 15mm?

A: The thickness tolerance for Brown Film Faced Plywood 15mm is usually +/- 0.5mm.

Q: What is the weight of Brown Film Faced Plywood 15mm?

A: The weight of Brown Film Faced Plywood 15mm can vary depending on the specific type and manufacturer. However, on average, it weighs approximately 1.3kg per square meter.

Q: What is the moisture content of Brown Film Faced Plywood 15mm?

A: The moisture content of Brown Film Faced Plywood 15mm should be between 8% to 12% to ensure durability and stability.