MDF/ HDF

ROCPLEX MDF/HDF offers a superior alternative to solid wood with its exceptional performance and stability. Constructed from wood fibers and resin, Medium Density Fiberboard (MDF) undergoes a precise drying and pressing process to produce dense and reliable sheets.

One of the key advantages of ROCPLEX MDF is its enhanced stability compared to solid wood. It exhibits excellent resistance to changes in humidity and heat, making it less prone to expansion and contraction. Unlike solid wood, which can warp or deform under varying environmental conditions, ROCPLEX MDF maintains its shape and structure, reducing the need for frequent maintenance and care.

We proudly provide a wide range of Wholesale MDF products to cater to diverse requirements and applications. With our expansive 40,000 square meters warehouse, we ensure efficient delivery and availability of MDF at any time, ensuring that you have access to the materials you need for your projects.

ROCPLEX MDF offers versatility and reliability across various applications, including cabinetry, doors, paneling, furniture, and more. Its consistent density and smooth surface make it ideal for precision cutting, shaping, and finishing, allowing for seamless integration into your designs.

Choose ROCPLEX MDF to experience the benefits of a high-grade composite material that outperforms solid wood in many aspects. With its stability, durability, and easy availability, ROCPLEX MDF is the go-to choice for professionals and DIY enthusiasts alike.

|

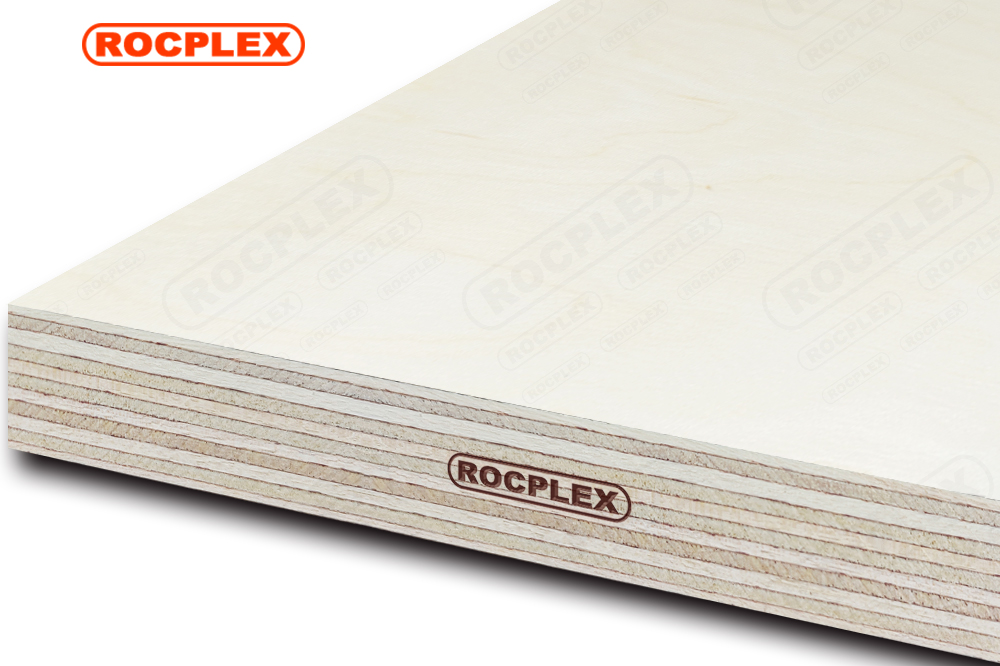

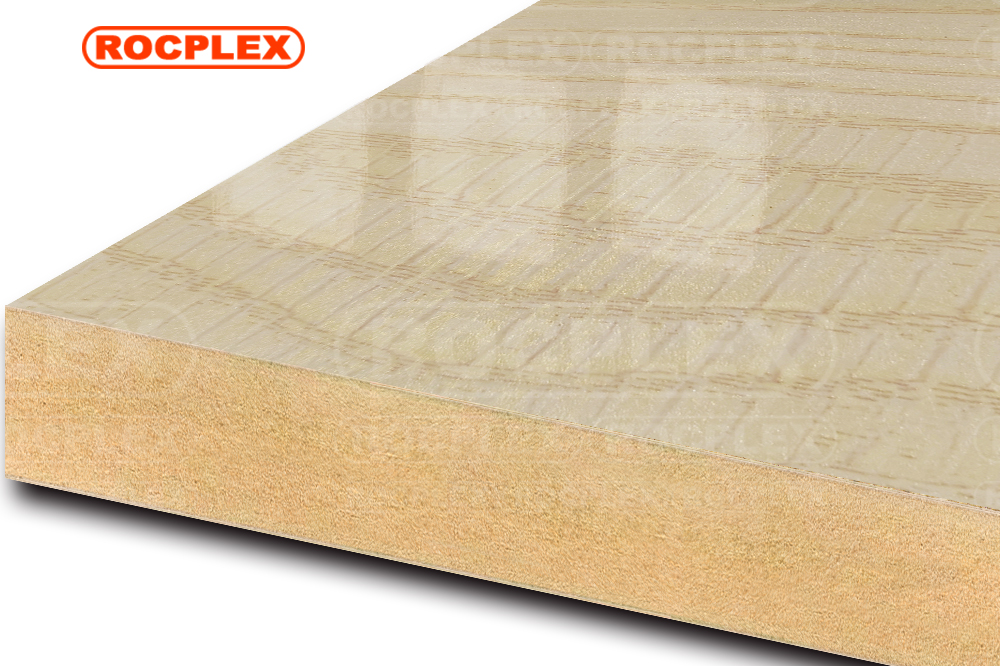

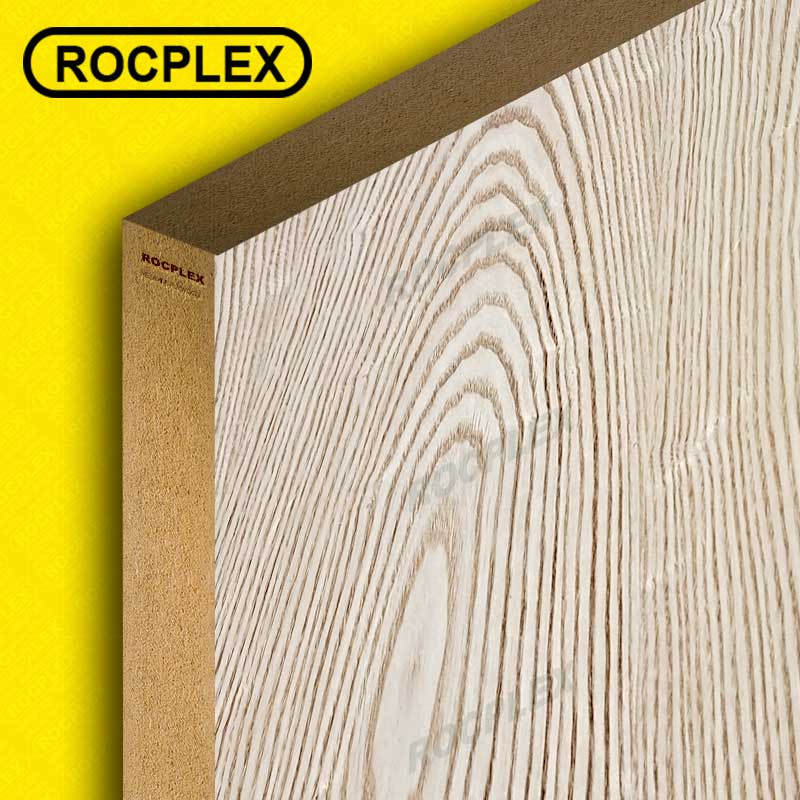

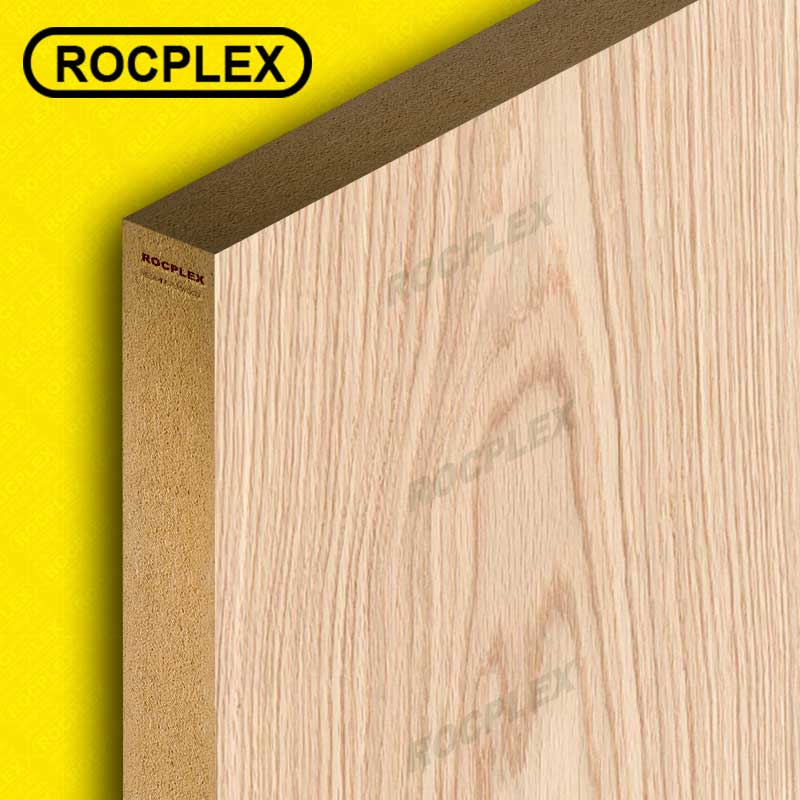

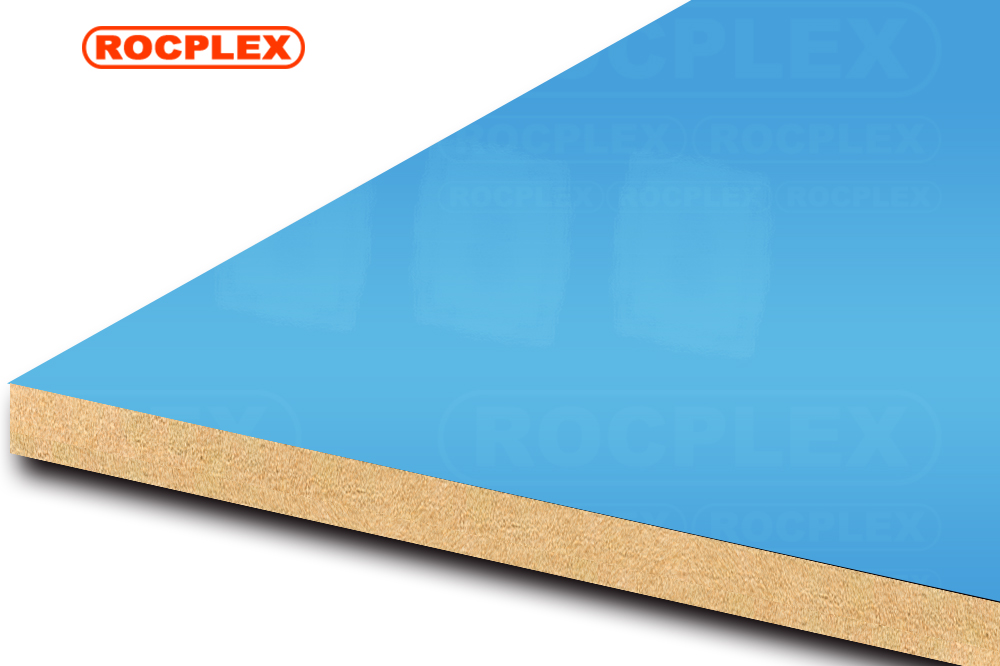

Face / Back: Raw MDF Melamine MDF Veneer MDF HPL MDF |

|

Grade: AA grade |

|

Color: raw MDF color, Solid colors, wood grain colors, fancy colors, stone colors |

|

Glue: E0 glue, E1 glue , E2 glue , WBP glue , MR glue |

|

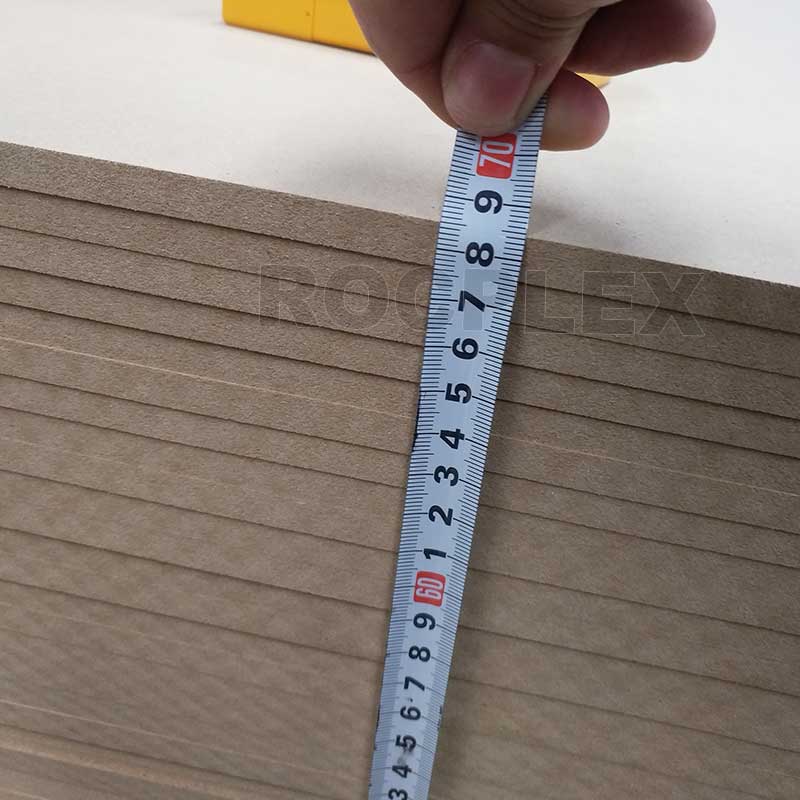

Thickness: 1-28mm (normal: 3mm, 6mm, 9mm, 12mm, 15mm, 18mm, 21mm) |

|

Specification: 1220mmX2440mm, 1250mmX2500mm, 915mmX1830mm, 610mmX2440mm, 610mmX2500mm |

|

Moisture Content: below 8% |

|

Density: 660 / 700 / 720 / 740 / 840 / 1200 kg/m3 |

Medium Density Fiberboard (MDF) and High Density Fiberboard (HDF) are engineered wood products that offer several advantages in various applications. Here are the advantages of MDF and HDF:

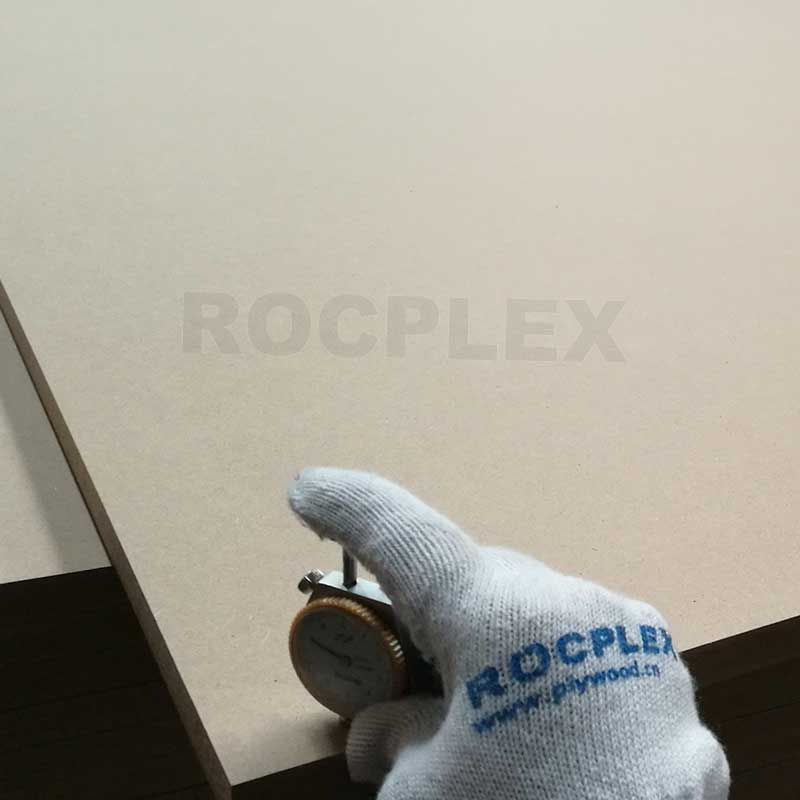

- Smooth and Homogeneous Surface: MDF and HDF have a dense and uniform composition, resulting in a smooth and consistent surface. This makes them ideal for applications where a flawless finish is desired, such as furniture and cabinetry.

- Versatility: MDF and HDF can be easily cut, shaped, and machined into intricate designs and profiles. They can be routed, drilled, and carved with precision, making them versatile for a wide range of applications and design possibilities.

- Stability and Dimensional Accuracy: MDF and HDF have excellent dimensional stability, meaning they resist warping, shrinking, and swelling when exposed to changes in humidity and temperature. This stability ensures that the finished products maintain their shape and size over time.

- Improved Screw Holding and Nailing: The dense composition of MDF and HDF provides excellent screw holding and nailing properties. They offer high resistance to screws pulling out and provide a solid hold, making them suitable for structural applications.

- Smooth and Clean Edges: MDF and HDF have smooth and clean edges when properly cut or routed. They are free from knots, voids, and grain patterns, allowing for seamless joinery and edge finishing.

- Superior Surface for Painting and Veneering: The smooth and homogeneous surface of MDF and HDF provides an ideal canvas for painting, veneering, and laminating. They have a consistent density that promotes uniform absorption of finishes and adhesives, resulting in a high-quality and professional appearance.

|

Container Type |

Pallets |

Volume |

Gross Weight |

Net Weight |

|

20 GP |

8 pallets |

22 CBM |

16500KGS |

17000KGS |

|

40 HQ |

16 pallets |

38 CBM |

27500KGS |

28000KGS |

- Furniture manufacturing, including cabinets, tables, chairs, bookcases, and shelves

- Interior design and decor, such as wall paneling, wainscoting, molding, trim, and decorative elements

- Doors and door frames for interior applications

- Exhibits and displays in retail and trade show settings

- Kitchen and bathroom components, including cabinet doors and drawer fronts

- Flooring underlayment and subflooring

- Backing for veneers and laminates

- Speaker cabinets and audio equipment enclosures

- Craft and DIY projects, including signs, plaques, and small furniture pieces

- Architectural millwork, such as moldings, baseboards, and trim

- Partitions and dividers in commercial and residential spaces

- Shelving systems and storage units

- Wall-mounted panels for acoustic treatment

- Educational and office furniture, such as desks, bookshelves, and filing cabinets