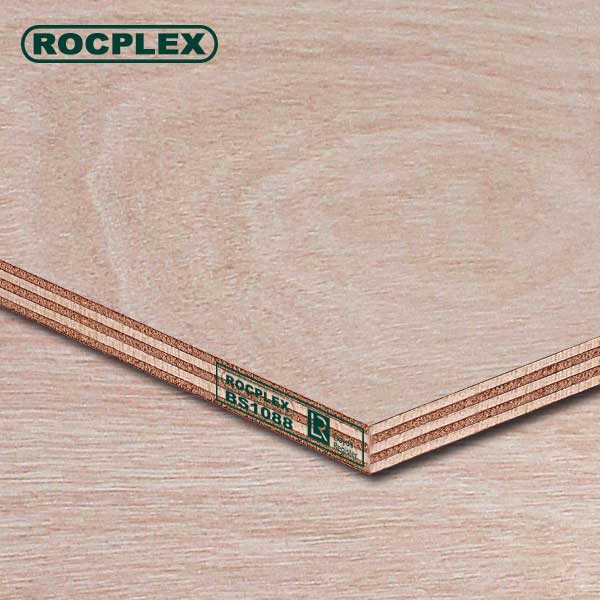

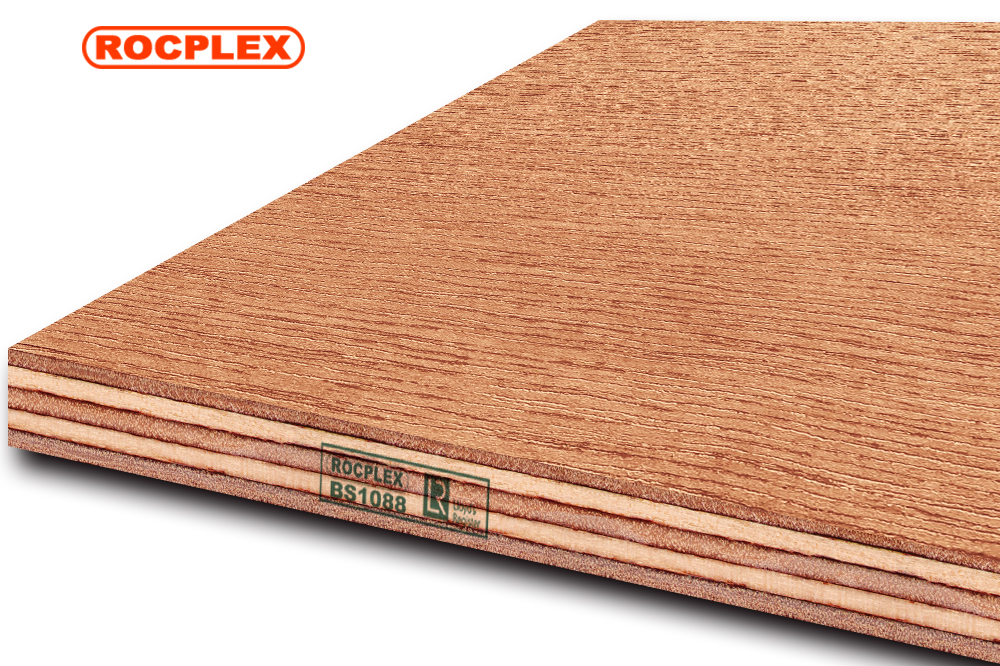

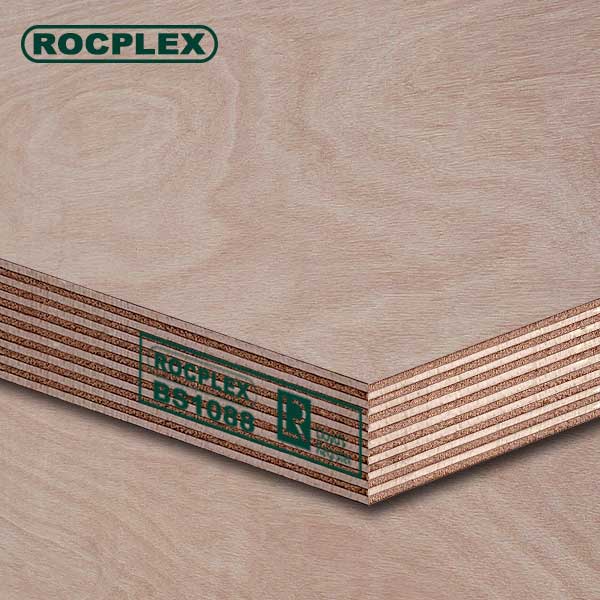

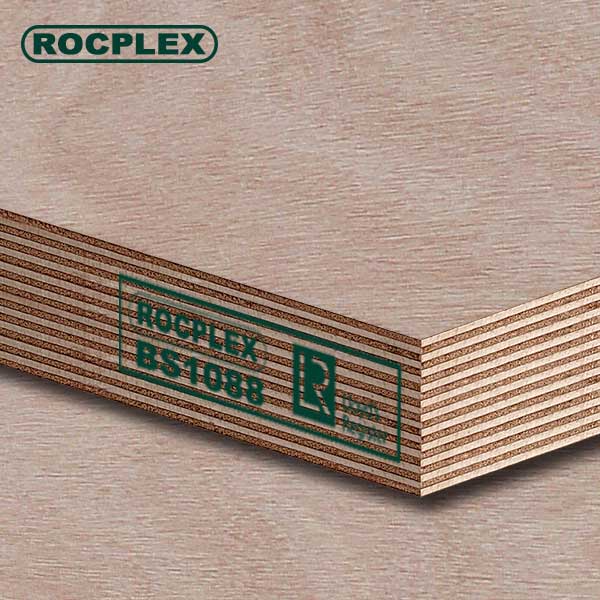

Marine plywood is a type of plywood that is specially designed for use in water-based environments. It is made from high-quality wood veneers that are bonded together with waterproof glue. Marine plywood is known for its durability, resistance to rot and warping, and ability to withstand harsh weather conditions.

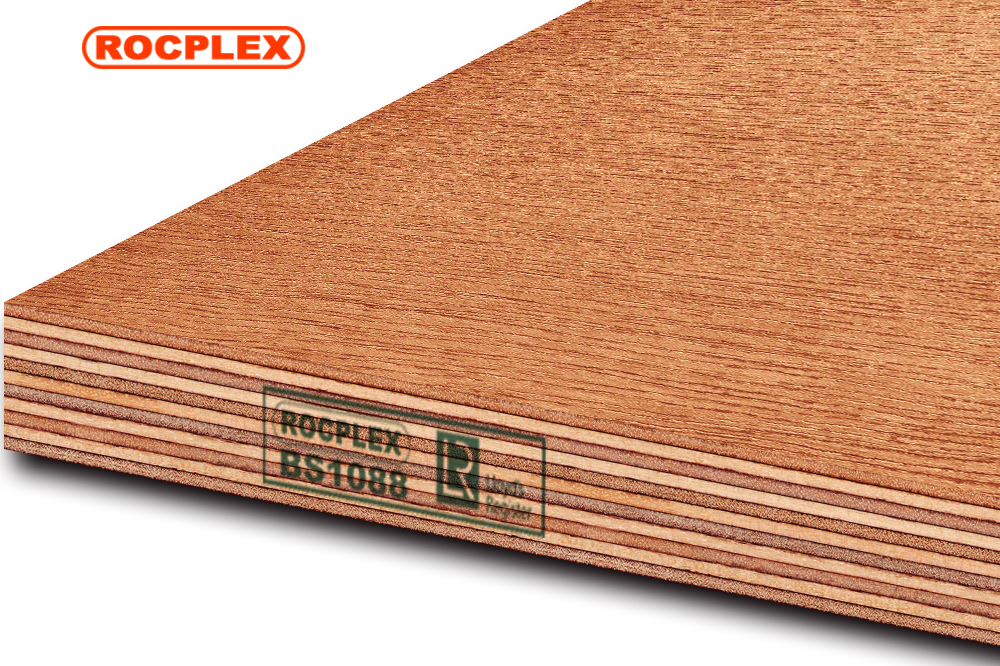

One of the main benefits of marine plywood is its ability to resist water and moisture. It is treated with special chemicals that prevent it from delaminating or deteriorating in wet environments. This makes it an ideal choice for use in boats, docks, and other water-based structures.

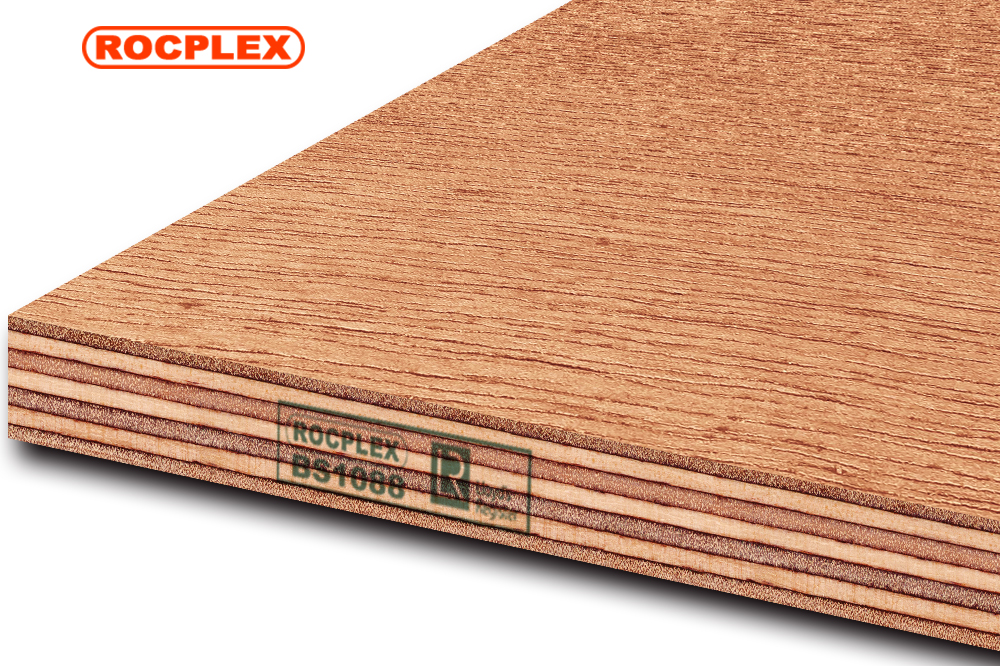

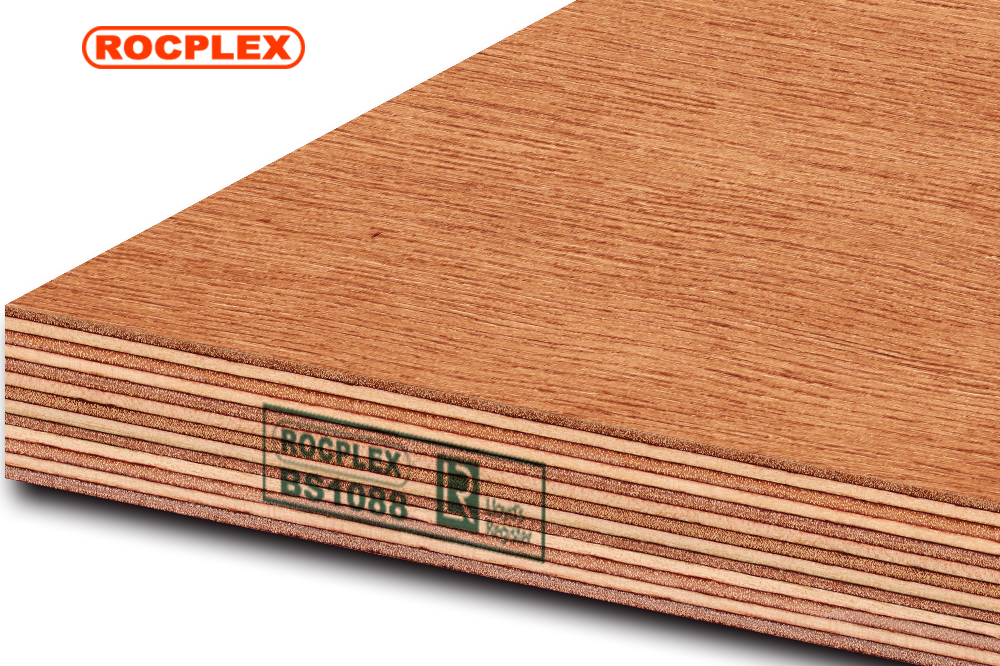

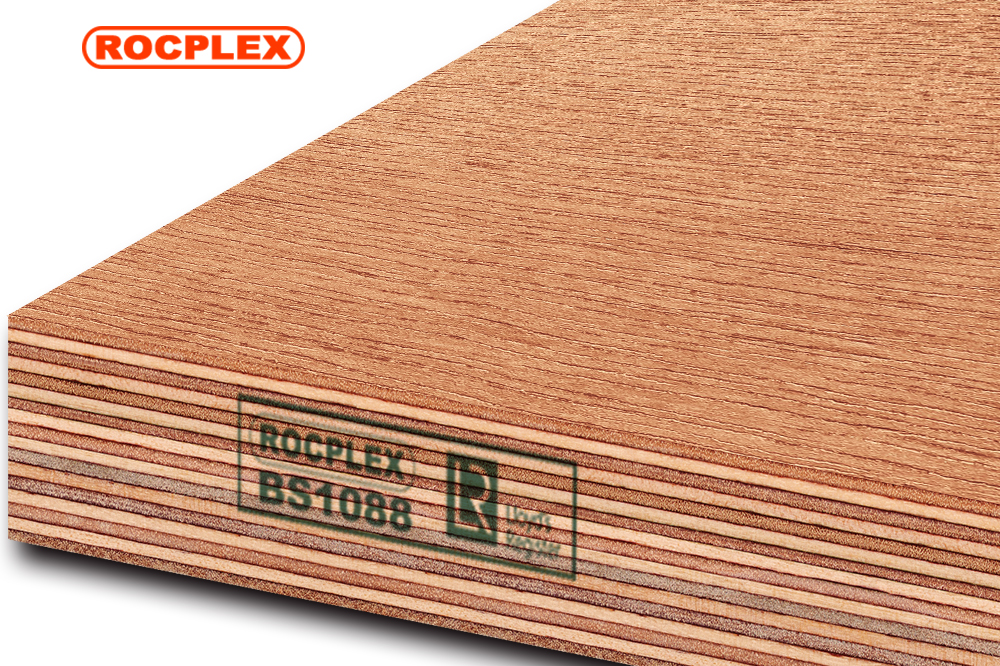

In addition to its water-resistant properties, marine plywood is also known for its strength and durability. It is designed to withstand heavy loads and high impact, making it suitable for use in construction, as well as in the marine industry.

When choosing marine plywood, it’s important to consider the type of wood used, the grade of the plywood, and the thickness. There are different types of wood used in marine plywood, such as Douglas fir, Western larch, and Okoume. The grade of the plywood indicates its quality, with A being the highest grade and D being the lowest. The thickness of the plywood varies depending on the intended use, with thicker plywood being more suitable for heavy-duty applications.

Marine plywood is a durable and high-quality plywood that is designed for use in water-based environments. Its water-resistant properties, strength, and durability make it an ideal choice for boats, docks, and other marine structures. When choosing marine plywood, it’s important to consider the type of wood used, the grade of the plywood, and the thickness to ensure the best performance for your project.