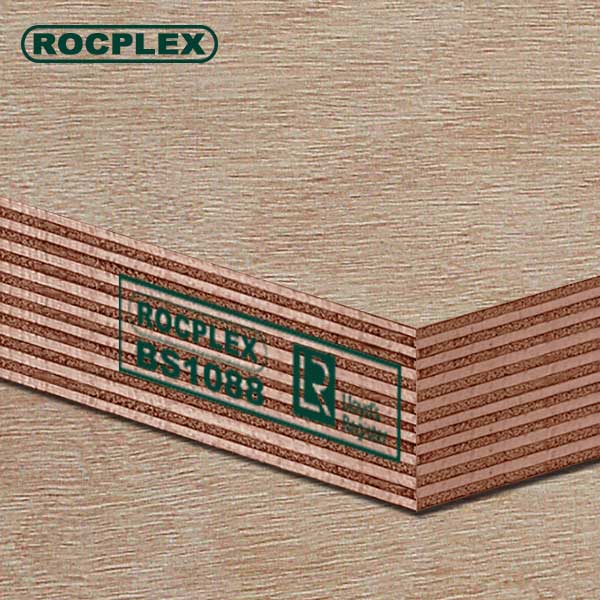

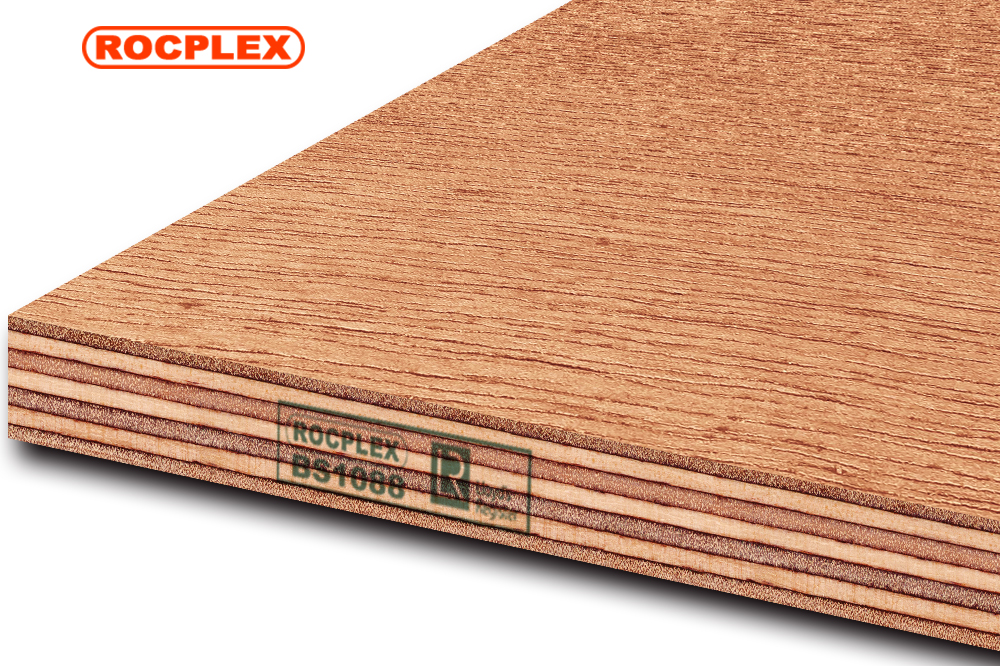

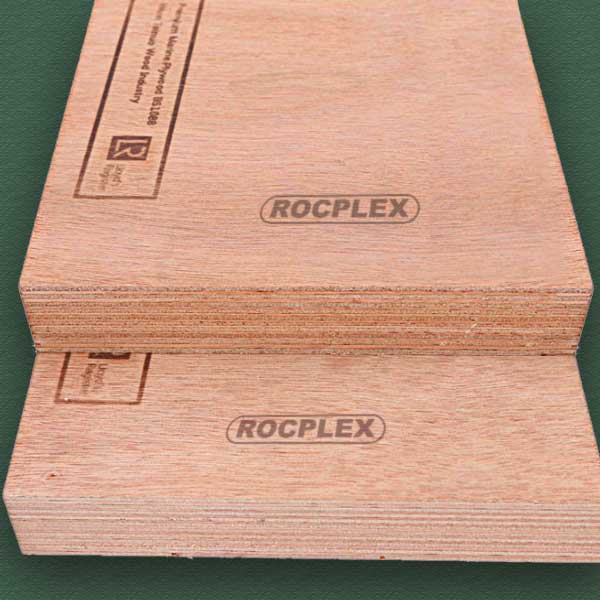

Beyond Ordinary Elevate Projects with 2440 x 1220 x 36mm BS1088 Marine Plywood

In the realm of construction and design, material selection plays a defining role in the outcome of any project. The Marine Plywood 2440 x 1220 x 36mm BS1088 emerges as a remarkable solution that goes beyond the ordinary, offering a range of benefits that elevate projects to extraordinary levels of strength, durability, and versatility.

|

Nomal Thickness |

Sheet Size (mm) |

Grade |

Density (kg/cbm) |

|

|

|

Glue |

Thickness tolerance |

Packing Unit (sheets) |

|

Face and back |

Core Materials |

Moisture |

|||||||

|

|

|

|

|||||||

|

1/8inch (2.7-4.0mm) |

1220×2440 |

B/B B/C C/C |

580 |

Okoume |

Okoume |

8-14 % |

Wtaerproof Super E0 |

+/-0.2mm |

150 / 400 |

|

1/2inch (12-12.7mm) |

1220×2440 |

550 |

Okoume |

Okoume |

8-14 % |

+/-0.5mm |

70 / 90 |

||

|

5/8inch (15-16mm) |

1220×2440 |

530 |

Okoume |

Okoume |

8-14 % |

+/-0.5mm |

60 / 70 |

||

|

3/4inch (18-19mm) |

1220×2440 |

520 |

Okoume |

Okoume |

8-14 % |

+/-0.5mm |

50 / 60 |

Please contact our sales team for more detailed information regarding Chinese plywood.

FAQ

Q: What is the difference between marine plywood and regular plywood?

A: Marine plywood is specifically designed and manufactured for use in marine environments and is made from high-quality hardwood veneers that are bonded together with waterproof adhesive. Regular plywood, on the other hand, is not designed for use in wet environments and may not be as durable or water-resistant.

Q: What is the thickness of Marine Plywood 2440 x 1220 x 36mm BS1088?

A: The thickness of marine plywood varies depending on the application, but the most common size is 2440 x 1220mm with a thickness of 36mm.

Q: What is the BS1088 standard for Marine Plywood 2440 x 1220 x 36mm BS1088?

A: BS1088 is a British Standard for marine plywood, which specifies the requirements for the materials, construction, and testing of marine plywood. To meet the BS1088 standard, marine plywood must be made from high-quality veneers, have a consistent thickness, and be free of defects such as knots, voids, and splits.

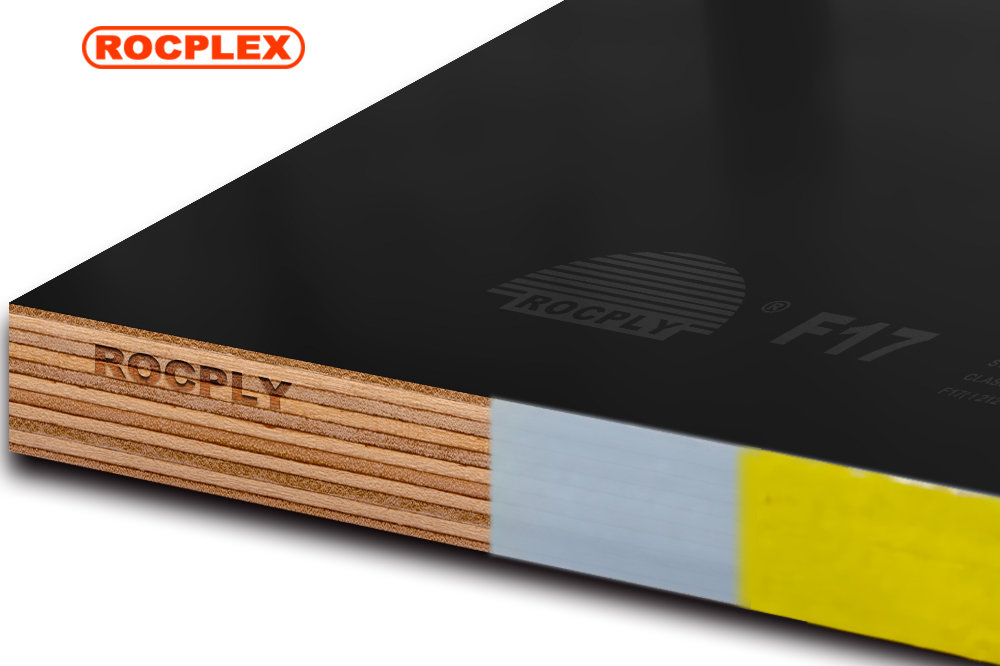

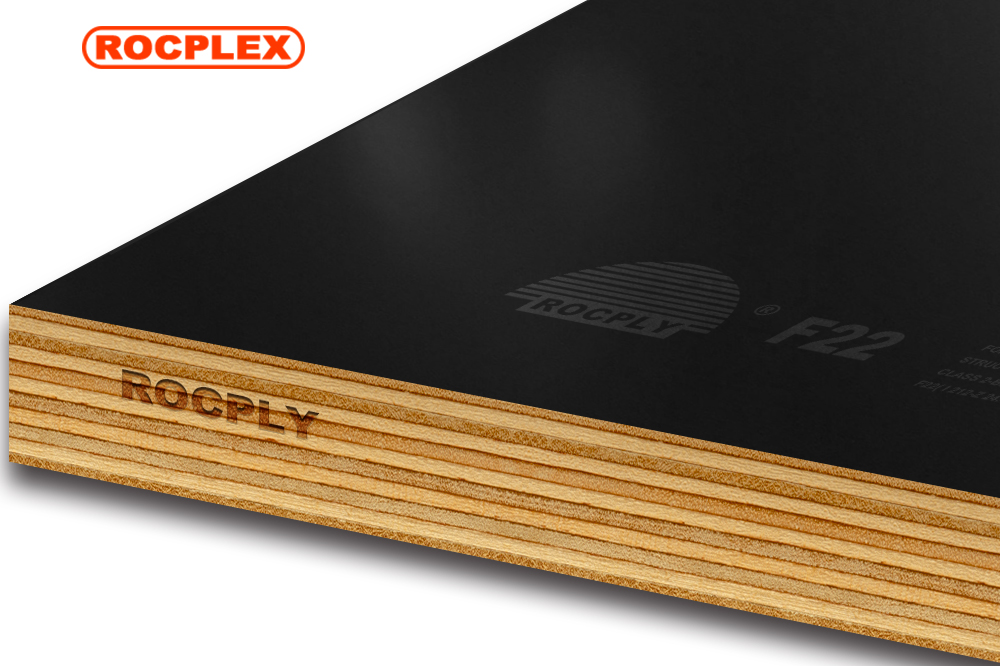

Q: What are the applications of marine plywood?

A: Marine plywood is commonly used in boat building and other marine applications due to its strength, durability, and resistance to moisture and decay. It is also used in construction, particularly in areas that are prone to moisture and dampness, such as bathrooms and kitchens.

Q: Is marine plywood more expensive than regular plywood?

A: Yes, marine plywood is generally more expensive than regular plywood due to its higher quality and durability. However, it is worth the investment for applications where strength, durability, and resistance to moisture and decay are essential.